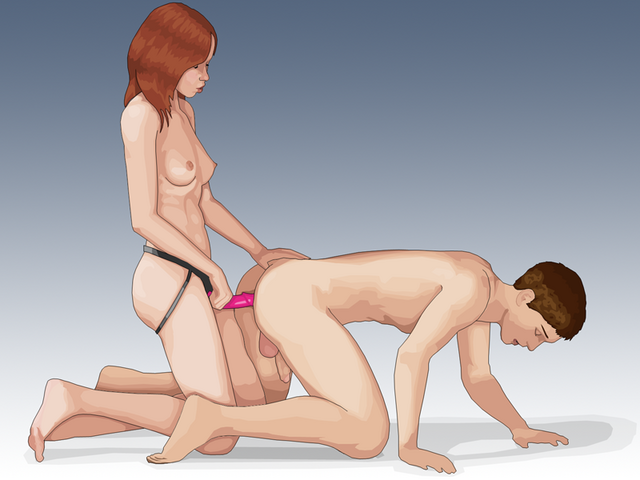

WEIGHT: 56 kg

Breast: Medium

1 HOUR:50$

Overnight: +30$

Services: Swinging, TOY PLAY, Massage, Toys / Dildos, Foot Worship

By using our site, you agree to our collection of information through the use of cookies. To learn more, view our Privacy Policy.

To browse Academia. Wight, J. Orlicky and W. Nevertheless, the MRP-II concepts are based on the waterfall model which encloses several weak points like: - Hierarchical and sequential planning procedure without direct recursive functions - Gross-Net-Method for material require-ment planning and order calculation centered on inventory - Time-phasing of depended required material using the Bill-of-Material BoM A new MRP concept can avoid these weak points by using the capabilities of Industry 4.

Here a new MRP-Concept is presented based on the Digital Control Twin DCT and the main functions are explained like: - Synchronous planning and order calculation of final products and required components - Actual-Target-Method for material requirement planning - Time-phasing of material requirements by production and material flow structure - Rule-based material requirements planning - Use of actual process data for proactive regulation - flexible choice of appropriate tools and algorithm depending on the actual data.

Material requirement planning MRP is a key element in managing resources in a manufacturing environment. MRP systems were developed to help companies manage dependent demand inventory and schedule replenishment orders. MRP systems have proven to be beneficial to many companies. This paper presents a new framework for manufacturing planning and control systems which we call iterative manufacturing planning in continuous time IMPICT that appears to have several advantages over the well-known material requirements planning MRP framework.

IMPICT explicitly considers capacity constraints and total system cost including tardiness to determine order sizes, order releaseldue dates, and operation schedules in a deterministic, multi-level, finite horizon, dynamic demand environment. Continuous time scheduling variables allow setups to be carried over from one period to the next. Material requirement planning is an essential activity in a manufacturing organisation to ensure that right quantity of materials are available at the right time and the inventories are not excessive.